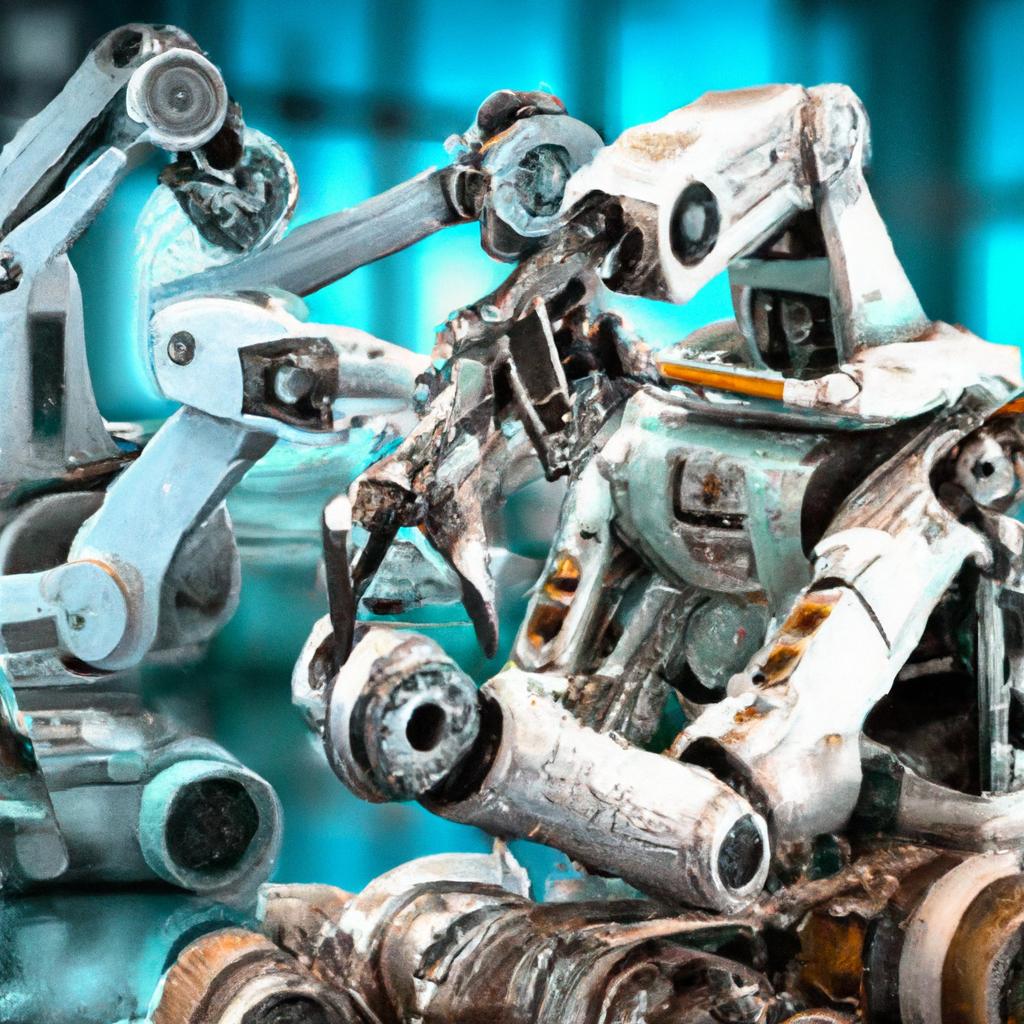

The Role of Robotics in Modern Manufacturing

In the age of technology, the landscape of manufacturing has been forever transformed by the integration of robotics. From assembly lines to warehouse operations, the role of robotics in modern manufacturing is undeniable. Join us as we delve into how these mechanical marvels are revolutionizing the industry and shaping the future of production.

Table of Contents

- Title: The Role of Robotics in Modern Manufacturing

- Challenges Faced by Manufacturers in Adopting Robotics Technology

- Benefits of Implementing Robotics in Manufacturing Processes

- Key Considerations for Companies Looking to Integrate Robotics into Production Lines

- Future Trends and Innovations Shaping the Landscape of Robotics in Manufacturing

- Q&A

- In Conclusion

Title: The Role of Robotics in Modern Manufacturing

Robots have revolutionized modern manufacturing processes, bringing efficiency and precision to the production line. With advancements in technology, robots are now capable of performing a wide range of tasks such as assembling, welding, painting, and packaging. This has significantly reduced the need for manual labor, making manufacturing processes faster and more cost-effective.

One of the key advantages of using robotics in manufacturing is the ability to handle complex tasks with accuracy and consistency. Robots can work non-stop, 24/7, without getting tired or making mistakes, leading to increased productivity and output. Additionally, robots are also capable of working in dangerous environments that may be hazardous to human workers, ensuring safety in the workplace. With the continuous development of robotics technology, we can expect to see even more innovative applications in modern manufacturing in the future.

Challenges Faced by Manufacturers in Adopting Robotics Technology

One of the main is the high initial investment required. Implementing robots in a manufacturing facility can be costly, not only in terms of purchasing the robots themselves but also in training employees to work alongside them. This financial barrier can be a significant hurdle for smaller manufacturers looking to automate their processes.

Another challenge is the fear of job displacement among the existing workforce. Many employees may be concerned that robots will take over their jobs, leading to layoffs and unemployment. It is essential for manufacturers to address these concerns and communicate the benefits of robotics technology, such as increased efficiency and productivity, which can ultimately lead to job growth and the creation of new roles within the company.

Benefits of Implementing Robotics in Manufacturing Processes

One major benefit of implementing robotics in manufacturing processes is the increase in efficiency and productivity. With robots taking over repetitive and mundane tasks, production can be carried out at a faster pace, leading to higher output levels. This not only reduces the time it takes to complete a task but also ensures a consistent level of quality in the products being manufactured.

Another advantage is the improvement in worker safety. By deploying robots to handle dangerous tasks or work in hazardous environments, the risk of injuries to human workers is significantly reduced. This leads to a safer work environment overall, as employees can focus on more complex and skilled tasks while leaving the dangerous work to the robots. Overall, the integration of robotics in manufacturing processes can lead to a more efficient, productive, and safer workplace.

Key Considerations for Companies Looking to Integrate Robotics into Production Lines

Incorporating robotics into production lines can revolutionize the way companies operate in the modern manufacturing landscape. However, before making the leap into automation, there are several key considerations that businesses need to take into account to ensure a successful integration.

<p>One crucial factor to consider is the <strong>cost-benefit analysis</strong> of implementing robotics. Companies need to weigh the upfront investment against the long-term savings in labor costs, increased efficiency, and reduced errors. Additionally, <strong>compatibility with existing infrastructure</strong> is essential to ensure a smooth integration process. It's important to assess whether the robotics can seamlessly work alongside current systems or if modifications are needed.</p>

Future Trends and Innovations Shaping the Landscape of Robotics in Manufacturing

Robotic technology is revolutionizing the manufacturing industry, enhancing efficiency, precision, and safety in production processes. With advancements in robotics constantly evolving, the future of manufacturing is becoming increasingly automated. Companies are increasingly turning to robotics to streamline operations and stay competitive in a fast-paced market.

One of the key trends shaping the landscape of robotics in manufacturing is the integration of artificial intelligence (AI) and machine learning. These technologies allow robots to learn and adapt to their environments, improving their performance and capabilities. Additionally, collaborative robots, or “cobots,” are gaining popularity for their ability to work alongside human operators, increasing productivity and flexibility on the factory floor. The future of manufacturing lies in embracing these cutting-edge technologies to drive innovation and growth.

Q&A

Q: What is the role of robotics in modern manufacturing?

A: Robotics play a crucial role in modern manufacturing by automating repetitive tasks, increasing efficiency, and improving productivity.

Q: How do robotics help increase efficiency in manufacturing processes?

A: Robotics help increase efficiency in manufacturing processes by performing tasks with precision and speed that human workers may not be able to achieve.

Q: Can you give examples of how robotics are used in modern manufacturing?

A: Robotics are used in modern manufacturing for tasks such as assembly, welding, painting, and packaging. They can also be used for material handling and quality control.

Q: How do robots improve safety in manufacturing environments?

A: Robots improve safety in manufacturing environments by taking on dangerous tasks that could potentially harm human workers. They can also handle hazardous materials without putting human health at risk.

Q: Are there any drawbacks to using robotics in modern manufacturing?

A: While robotics offer many benefits to modern manufacturing, some drawbacks include high initial costs for implementation and potential job displacement for human workers in certain industries.

Q: How do advancements in robotics technology impact the future of manufacturing?

A: Advancements in robotics technology are shaping the future of manufacturing by allowing for greater customization, increased flexibility, and the ability to meet changing market demands more efficiently.

In Conclusion

As we continue to navigate the ever-evolving landscape of modern manufacturing, one thing is clear: robotics are here to stay. Their precision, efficiency, and ability to adapt to complex tasks have revolutionized the way we produce goods. With advancements in technology accelerating at a rapid pace, the role of robotics in manufacturing will only continue to grow. As we look towards the future, it is evident that these machines will play a crucial role in driving innovation, improving processes, and ultimately reshaping the face of the industry. So let us embrace this new era of manufacturing and welcome the possibilities that robotics bring. The future is bright, and it is powered by automation.